Sponsored by ADVICS North America

As a technician, you could likely carry out a brake job in your sleep, but with automotive technology constantly evolving, what used to be a straightforward service can now require some additional steps and considerations to ensure that your customer’s brakes are in good working order. This is especially true when performing brake service on vehicles equipped with ADAS or Advanced Driver Assistance Systems.

To make sure you’re prepared to service vehicles with this new (and evolving) technology, we asked our technicians to share their tips and tricks so that you’re able to confidently handle any brake job that comes your way.

Don’t Overcomplicate It

While the software, sensors and specific calibrations that come along with with ADAS may sound intimidating, the mechanics of a braking system on a vehicle equipped with this technology are the same as any vehicle at their core. If you have the knowledge and skills to complete a quality brake job, you are capable of servicing brake systems with ADAS.

Always Match the Factory Fit

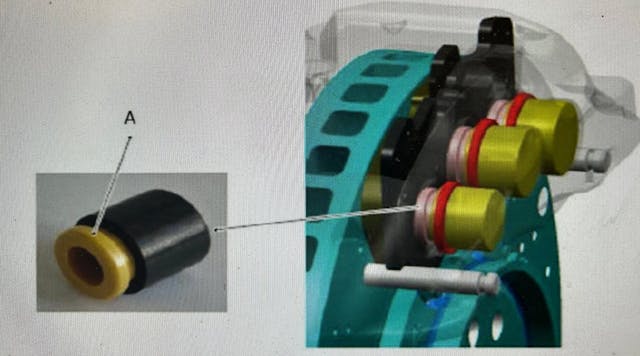

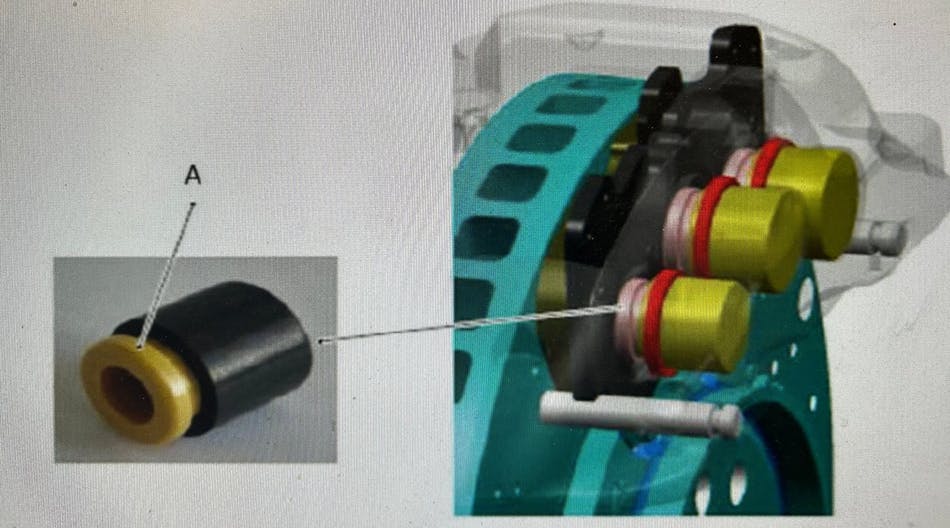

With the advanced technology that comes with ADAS-equipped vehicles, it’s crucial to take into account that replacement brake components must align with the programmed value that the vehicle rolled off the line with. This means that you’ll have to ensure that the parameters originally programmed for the vehicle’s assisted cruise control are restored before the customer leaves your shop. This will only be successful if you are using ultra-premium quality brake parts that are tested to meet or exceed OE standards for vehicle-specific fit.

Align with OE Specifications

In order to ensure a brake pad will function properly with ADAS, you need to confirm that the pad meets OE specifications. This is easy to do when using ADVICS ultra-premium brake pads, as each part is designed and manufactured to precise OE tolerances for make and model. By replacing the brake parts in question with those which are designed to provide a precise factory fit, you ensure that the calibration of the ADAS will remain consistent. This means that ADAS will function exactly as it is supposed to once your customer leaves the shop.

Consider the Brake Pad Material & Quality

Finally, it’s critical that you match the friction material of the replacement brake pad to that of the original equipment. This is necessary because the new brake pad needs to be able to perform braking events with the same stopping power and responsiveness as the original to ensure safe stopping with ADAS. For instance, if the vehicle was originally outfitted with a ceramic brake pad from the factory, you must replace that brake pad with one of the same quality in order to retain all functionality of ADAS.

With proper maintenance of the brake system being an essential component to the safe operation of a vehicle, it’s critical to check each of these considerations off your list when preparing to perform a brake job on an ADAS-equipped vehicle. Keep in mind that vehicles with ADAS are not necessarily more complicated to work on, they simply require a few extra checkpoints to ensure that the brake system can do what it’s meant to do – stop.